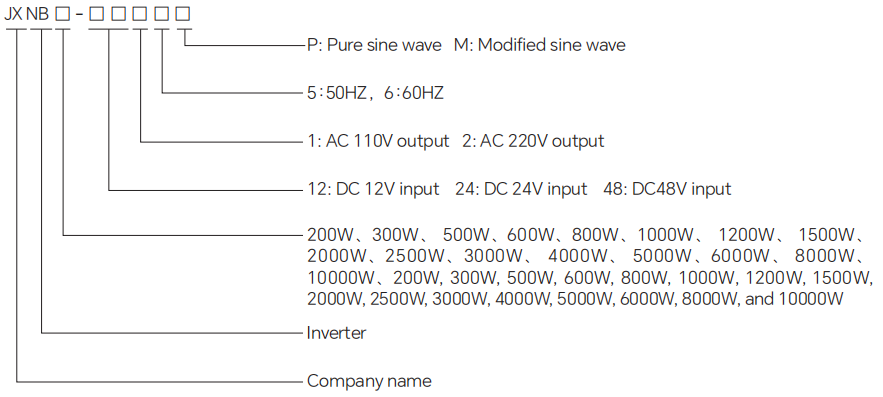

Model and Its Meaning

For example JXNB1000-2425P,

Juxing 1000W inverter, DC 24V input, AC 220V output, 50HZ, pure sine wave

Safety Instructions

Warning: Please read the safety instructions carefully when installing and using the inverter.

● To reduce the risk, please do not expose the inverter power supply to harsh environments such as rainy days, snowy and frosty days, foggy days, and places with grease or a lot of dust during installation; Do not install the inverter in a sealed place; Do not cover and block the vents, as the inverter power supply will be damaged due to overheating.

● The inverter power supply should avoid the fire source and electric shock, and the electric wires that do not meet the specifications or do not meet the standard may damage the inverter power supply.

● Because the inverter power supply equipment itself contains components that are prone to electric arcs, it can not be installed in flammable and explosive environments, including batteries and flammable fabrics. Do not install next to equipment without fire protection, including gasoline engines, fuel drums, or other component systems located next to the fuel.

● When connecting the battery, if the acidic substance of the battery comes into contact with the skin or clothing, rinse immediately with water and soap. If the acidic substance enters the eyes, wash the eyes with water for at least 20 minutes and seek medical treatment immediately.

● Do not allow any smoke, sparks, or flame around the battery or engine.

● Please do not put metal tools on the battery, which is likely to cause damage to the battery or other electronic components due to short circuit sparks.

● It is strictly prohibited to put small metal objects such as iron needles and iron pins into the product; Keep away from water sources and do not spill water on or inside the product.

● Do not allow the children to operate this product, and do not touch the terminals and output sockets of this product with fingers to prevent electric shock. Do not replace the electrical switch with the inverter switch on the product.

● Ensure that the output AC is stable before carrying the load, otherwise it may damage the product (The product is used when the switch is started, that is, if the product switch is turned on first, and then the load switch is turned on, it will produce larger current).

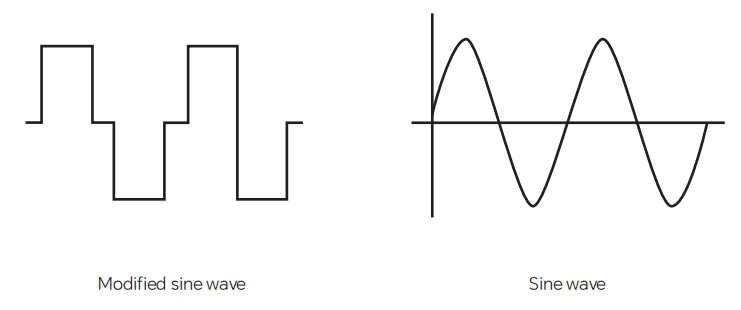

● If the output AC of this product is of square wave (Modified sine wave), it can only carry the resistive load, such as light bulbs, energy-saving lamps, electric cookers, rice cookers, and products with switching power supplies, but can not carry inductive load products, such as refrigerators, hair dryers, electric drills, motor products, otherwise it will lead to product damage.

● If there is a problem with the product, please do not open it by yourself to prevent electric shock, and be sure to send it to professional maintenance personnel for repair.

● Scrap precautions: When scrapping the inverter, please note that the electrolytic capacitor of the main circuit and the electrolytic capacitor on the printed board may explode during incineration. Burning plastic parts such as the front panel will produce toxic gases. Please dispose of it as industrial waste.

Waveform comparison between sine wave and modified sine wave

Product Features and Product Applications

Product Features

Pure sine wave output or modified sine wave output

High-efficiency, lightweight type

The LED indicates the status of the load

Fully automatic control cooling fan (Temperature control)

Microprocessor designInternal undervoltage/overload/short circuit/overvoltage/insufficient battery energy alarm/overtemperature alarm devices

Product applications

Electric tool series: Electric saw, drilling machine, grinder, sandblasting machine, stamping machine, weeder, air compressor, etc.

Office equipment series: Computer, printer, monitor, copier, scanner, etc.

Household appliance series: Vacuum cleaner, fan, fluorescent lamp and incandescent lamp, electric sewing scissors, sewing machine, etc.

Kitchen appliance series: Microwave oven, refrigerator, freezer, coffee maker, blender, ice maker, baking oven, etc.

Industrial equipment series: Metal halide lamp, high-pressure sodium lamp, ships, vehicle-mounted, solar energy, wind power generation, etc.

Electronic field series: TV recorders, game machines, radios, power amplifiers, music equipment, monitoring equipment, terminal equipment, servers, intelligent platforms, satellite communication equipment, etc.

Usage Environment and Operation Guide

The installation position of the inverter power supply should meet the following requirements:

● Dry: Do not expose the inverter power supply to wet environments such as rainy, snowy, frosty, and foggy days, and do not allow water droplets or oil on the inverter power supply.

● Cooling: It is recommended to use a good cooler and control the ambient temperature between -10° C and 40° C.

● Safety: Do not install around flammable and smoking fuel storage and fuel engines.

● Ventilation: Keep at least 30 mm of ventilation space around the power supply, and ensure that there are no obstructions in the vents behind and under the inverter power supply.

● Dust: The inverter power supply cannot be installed in a dusty environment, such as a large amount of dust, wood chips, and some shavings as well as other harsh environments, which will lead to power failure.

● Battery or battery pack: Do not use too long electric wire. The inverter power supply should be isolated from the battery, and the battery can not be exposed to the outside, as it produces a gas with strong corrosion, which will damage the inverter power supply over the course of time.

● Ground connection: Please safely ground the grounding end of the inverter power supply with a conductor wire or safely connect the grounding end with a conductor wire to your load. (For example: Earthing panel for cars, etc.).

Operation guide

Warning: There is a high-voltage current inside the product, which should be cautioned carefully to ensure safety. Non-professional personnel are strictly prohibited from disassembling or transforming the product, and the Company will not take responsibility if there is any violation. Please follow the following guide to operate, and the Company will not be responsible for any loss caused by non-compliance with this guide.

Inverter operation guide:

Power options. An accumulator/battery/vehicle-mounted battery must be used to make the input voltage at 12V/24V/48V and suitable for the product. (It will damage the machine if the input voltage of the machine is higher than the rated value by 0.6 times or more). Generally speaking, for a 12V inverter, it will choose a power supply with a capacity of 30AH or more for 300w machine, a power supply with a capacity of 100AH or more for 1000w machine, and the like.

● Connect the inverter to the power supply. Keep the switch in the OFF (off) position (Including inverters and appliances). Get power supply from the battery. The black wire connected to the black terminal is the negative terminal, and the red wire connected to the red terminal is the positive terminal.

● The inverter is connected to the electrical appliance. Ensure that the load power of the inverter is within the specified power range, and should not exceed the maximum power of the inverter when the power supply is turned on. When the inverter is connected to the equipment and power supply, be sure to turn on the switch on the inverter and appliance. Generally speaking, the starting power of the equipment is several times, or even 10 times, of its nominal power. During startup, if the inverter sends a continuous alarm, and the red light keeps flickering, it means the inverter overload protection at this time. The solution is to turn off the inverter switch and some equipment, and then restart the inverter. If this solution fails, you need to use an inverter with larger power. The inverter restarts twice during overload.

● Input undervoltage protection. When the battery voltage is very low, the inverter will sound an alarm, and if the alarm sounds once, it indicates that the DC power supply is insufficient, and the battery needs to be charged. When it is lower than 9V to 9.5V for 12V input voltage, lower than 18V to 19V for 24V input voltage, and lower than 38V to 40V for 48V input voltage, the AC output will automatically shut down, and the red light will flicker as the alarm sounds.

● Input overvoltage protection. When the input voltage reaches 15V to 15.5V for the 12V inverter, the input voltage reaches 30V to 31V for the 24V inverter, and the input voltage reaches 60V to 62V for the 48V inverter, the inverter will give an alarm, the alarm sounds twice, the red indicator light will flicker as the alarm sounds, and the AC power will stop outputting at the same time.

● Short circuit protection. When a short circuit occurs, the output equipment will shut down.

● Opposite polarity input protection. When the battery is connected in the opposite direction, the fuse will burn up to protect the equipment.

● Overheat protection. When the internal temperature of the inverter exceeds 70 degrees Celsius, the inverter will sound an alarm, the alarm sounds 3 times, the red indicator light will flicker as the alarm sounds, and the AC power will stop outputting. The inverter restores AC output until the internal temperature of the inverter returns to normal.

● When charging, the terminal and the input battery are connected with a wire, and the terminal is the output end of the charger. Turn on the charger switch (There is only one indicator above the switch), and when the power plug is plugged in, the indicator will light up, if it is in red, it means that the machine is on charge. If it is in green, the battery is fully charged or the terminal is not properly connected to the battery.

● If the machine is only equipped with the charger without automatic switching, then it is best to turn off the inverter switch when charging (There are two indicators above the switch), so that the whole machine reduces the inverter standby loss and shortens the charging time.

● The charger has no output fault, and you can check whether the built-in fuse is damaged. Operation guide: Plug the AC input cable into any output socket of the inverter, and then turn on the inverter switch. If it is an inverter-priority type, the inverter starts to work first, and switches to the mains power supply when the battery energy is insufficient. If it is the mains-priority type, the mains works first, and when the mains is turned off, it switches to the inverter working in order to provide energy for the load.

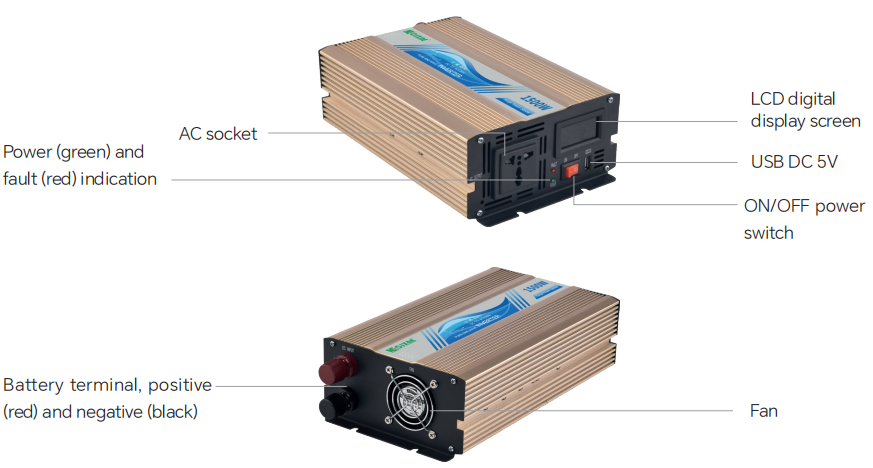

Component Schematic Diagram and Wiring

Note: This is a manual. The output voltage can be 100V/110V/120V/50Hz/60Hz, or 220V/230V/240V/50Hz.

Please take this as a reference. This manual is for explanation only and is not exactly equivalent to the product. The indicator on the AC side

POWER/WORK: This indicator is turned on when the inverter is running.

FAULT: This indicator is turned on when undervoltage, overvoltage, short circuit, overload, or overheating occurs.

CHARGING: It is for the display of inverter charging. When the battery is charged, the indicator turns red. When it turns green, the charging is completed.

Inverter Illustration

Modified Sine Wave 800W-1200W, Puer Sine Wave 800W-1200W

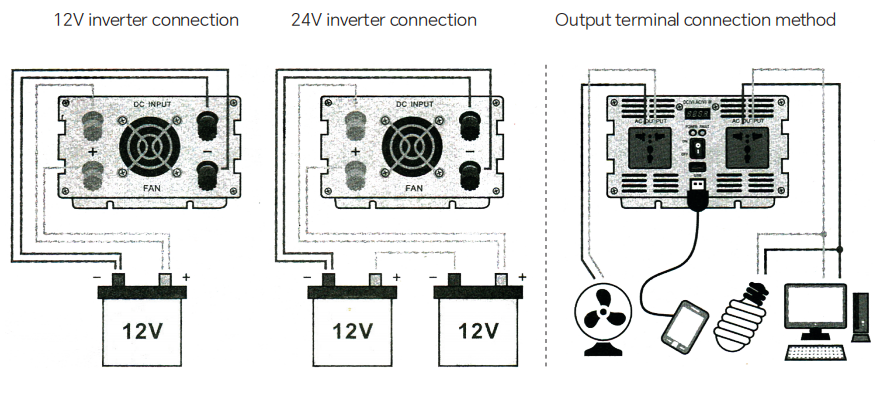

Wiring Schematic Diagram

Note: 48V and 24V Inverters should be connected to multiple batteries in series.

Common Faults and Troubleshooting Methods

1. Buzzer alarm. When the inverter in use makes a sound, it will beep even at a lower sound, and this is possible because the output current of the inverter is of a modified sine wave. If it is pure sine wave, it is because the load is relatively large. Please wait for 20 seconds. If the equipment does not work properly after 20 seconds, please shut down, so as not to waste power. 2. TV interference. Minimize interference through filters. In some cases, very weak interference will become obvious, and you can try the following operations: A. Keep the inverter away from the TV and TV antenna. B. Try to change the direction of the cable of the TV signal and the TV antenna to minimize interference. C. Choose a high-quality cable TV screen. 3. The inverter does not respond. A. The battery is in poor contact with the inverter. Reconnect the battery. 4. The output voltage is too low. A. Overload. If the load power exceeds the rated power, turn off some appliances and then turn on the inverter again. B. If the input voltage is too low, ensure that the input voltage is within the rated range. 5. Undervoltage alarm. A. The battery is dead. Replace the battery. B. The battery voltage is too low or the battery is improperly connected. Replace the battery, check the connection or clean the connection terminal with a dry cloth. 6. The inverter has no output. A. The battery voltage is too low. B. If the load is too high, shut down some appliances and restart the inverter. C. Inverter overheat protection. Cool the inverter and place it in a ventilated place. D. If the inverter fails to start, restart the inverter. E. The two poles are connected in reverse, and the fuse is burned. Replace with the fuse of the same specification, and reconnect. 7. The inverter does not run. Check whether the power switches, fuses, and batteries are properly connected. We offer a maximum normal quality warranty period of 18 months from the date of sale.

We will not provide warranty in the following cases:

1.Unusual damage and wear;

2. Damage during transportation;

3. Unusual use and operation & installation;

4. Explosion due to usage in improper environment;

5. Damage caused by negligence or accident,

Inverter Specifications

| Model | JXNB1000 |

| Rated power | 1000W |

| Max. power | 2000W |

| Rated output voltage | AC 110V±5% |

| AC 220V±5% | |

| Frequency | 50HZ±0.5HZ or 60HZ±0.5HZ |

| DC input voltage | 12/24/48V |

| Output current form | Pure sine wave P / modified sine wave(Square wave) M |

Inverter Size Form

| Model | JXNB1000 |

| Size (mm) | 285*160*80 |

| Net weight (g) | 2330 |

Statement: The product size in the picture is different from that of actual product, and the latter shall prevail. Products are subject to constant updating with changes, and please contact the Company if you need more information.

Do not disassemble the inverter without permission!

Transportation, Storage and Quality Guarantee Period

Transportation Transportation shall meet the following requirements:

There is an awning equipped in transportation, and there should be no violent vibration, impact, etc.;

Handle gently during transportation or handling.

Storage

Products should be stored in the original packaging box before use. The ambient temperature of warehouse storing the products is of -40° C ~ 70° C, with a relative humidity of 20% - 90%. The warehouse is not allowed to store various harmful gases and flammable, explosive and corrosive chemicals, and the equipment should not be subject to heavy load, strong mechanical vibration and impact, etc.

Warranty period

The product quality warranty period is 12 months from the ex-factory date, provided that the user complies with the installation and use regulations of the product.